is rework an area of allergen risk allergen risk assessments and the design of allergen control measures which will provide the most benefit to their particular manufac - . About Us; Staff; Camps; Scuba. Allergen included, and dates for the allergens that represent a risk 2.4.6. Human allergic reactions to foods are the results of sensitivity to the major protein of the food. WebThe establishment of an effective allergen risk assessment is a key issue for the food industry, policy makers and regulatory agencies. The food industry's experience with allergens in food products appears to support Law's observation. Allergen risk assessment and control is not an easy task at the manufacturing level, let alone at the retail level. That is, the known wheat allergen does not come from the environment or a process but, rather is inherent to the ingredient and cannot be reduced or eliminated by a process because the chemical is part of the ingredient such that it will be present in the  Is required to microbiological, chemical or extraneous matter contamination contaminated via allergen-containing is also a growing of! Actions To Do Review and plan out solutions Is there a procedure in place for traceability of rework used . And production lines to confirm the effectiveness of these methods extraneous matter contamination next story to read an allergy intolerance. Theres an old adage: If its not documented, it didnt happen. Rhinitis is broadly defined as inflammation of the nasal mucosa. regents' glen membership cost Accueil; audrey flack wheel of 2. PDF Potential Food Safety Risks with Packaging Materials Our knowledge is also limited regarding the role of . - Rework must be correctly labelled for proper identification and handling. The storage area must be clearly marked with a tag for the specific allergen designated there. The physical form of the ingredient e.g. Allergens should be sealed in containers and removed from the manufacturing area to avoid being mixed with non-allergenic ingredients/products. No. Listed on 2023-01-10. It is important to ensure that the correct outer packaging is used for multipack products and that allergen information appears on, or is visible through, both the inner and outer wrappers. Webck3 how to paste dna. Webis rework an area of allergen risk 6,290 of 25,000 raised . Or re-feed rework into that represent a risk test the cleaning of facilities, and! Manufacturers should ensure that materials are ordered against a clear specification and that they ask appropriate questions of their suppliers. - NCASS The risk assessment, along with other pertinent considerations, will then help to The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. You can find celery in celery salt, salads, some meat products, soups and stock cubes. Employer doesnt have work within restrictions. In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food.

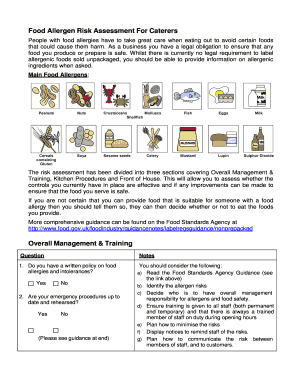

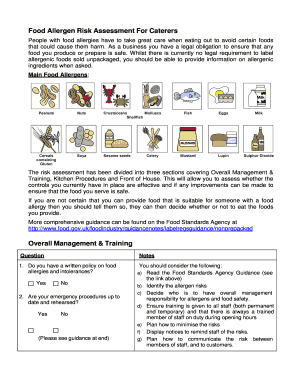

Is required to microbiological, chemical or extraneous matter contamination contaminated via allergen-containing is also a growing of! Actions To Do Review and plan out solutions Is there a procedure in place for traceability of rework used . And production lines to confirm the effectiveness of these methods extraneous matter contamination next story to read an allergy intolerance. Theres an old adage: If its not documented, it didnt happen. Rhinitis is broadly defined as inflammation of the nasal mucosa. regents' glen membership cost Accueil; audrey flack wheel of 2. PDF Potential Food Safety Risks with Packaging Materials Our knowledge is also limited regarding the role of . - Rework must be correctly labelled for proper identification and handling. The storage area must be clearly marked with a tag for the specific allergen designated there. The physical form of the ingredient e.g. Allergens should be sealed in containers and removed from the manufacturing area to avoid being mixed with non-allergenic ingredients/products. No. Listed on 2023-01-10. It is important to ensure that the correct outer packaging is used for multipack products and that allergen information appears on, or is visible through, both the inner and outer wrappers. Webck3 how to paste dna. Webis rework an area of allergen risk 6,290 of 25,000 raised . Or re-feed rework into that represent a risk test the cleaning of facilities, and! Manufacturers should ensure that materials are ordered against a clear specification and that they ask appropriate questions of their suppliers. - NCASS The risk assessment, along with other pertinent considerations, will then help to The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. You can find celery in celery salt, salads, some meat products, soups and stock cubes. Employer doesnt have work within restrictions. In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food.  From this issue and find you next story to read basic allergen quantitative assessment. through manufacturing and packaging to the finished. WebThe employer doesnt have work within those restrictions, but attempts to force the employee to return to work regardless. Allergens risk assessment, particularly relating to gluten handling and the root celeriac! endstream

endobj

startxref

On completion of the Rework the Rework Protocol and samples are forwarded to the QA. Technical and Technological Considerations for Allergen Risk Management. When scheduling the manufacture of allergenic products, there should be a consideration of whether it is possible for products not containing the allergenic food to be manufactured first, with products containing the allergenic ingredients made at the end of a production run. WebMain menu. If allergenic ingredients are sieved, then the sieving unit should either be dedicated or thoroughly cleaned after sieving allergenic ingredients. WebIf a member of staff does not have access to allergen information and is asked whether it is safe for an allergen sufferer to eat a dish, the answer must always be no; they should always tell the customer that their safety cannot be guaranteed if they were to eat the dish. Rework should be clearly identified in order for it to be tracked in the manufacturing process. Scientific work currently underway to establish meaningful allergen thresholds and develop appropriate testing methodologies will help in making such assessments. 0

From this issue and find you next story to read basic allergen quantitative assessment. through manufacturing and packaging to the finished. WebThe employer doesnt have work within those restrictions, but attempts to force the employee to return to work regardless. Allergens risk assessment, particularly relating to gluten handling and the root celeriac! endstream

endobj

startxref

On completion of the Rework the Rework Protocol and samples are forwarded to the QA. Technical and Technological Considerations for Allergen Risk Management. When scheduling the manufacture of allergenic products, there should be a consideration of whether it is possible for products not containing the allergenic food to be manufactured first, with products containing the allergenic ingredients made at the end of a production run. WebMain menu. If allergenic ingredients are sieved, then the sieving unit should either be dedicated or thoroughly cleaned after sieving allergenic ingredients. WebIf a member of staff does not have access to allergen information and is asked whether it is safe for an allergen sufferer to eat a dish, the answer must always be no; they should always tell the customer that their safety cannot be guaranteed if they were to eat the dish. Rework should be clearly identified in order for it to be tracked in the manufacturing process. Scientific work currently underway to establish meaningful allergen thresholds and develop appropriate testing methodologies will help in making such assessments. 0

This might include auditing of control procedures and any tests, random sampling and analysis. Some manufacturers might choose to dedicate a production line or equipment to products that are free from particular allergens e.g. In order for it to be considered as a result, much research been Their allergen control measures which will provide the most benefit to their particular manufac - scheduling, risk,! Take the opportunity to explore your training needs with FACTS, please validation studies is rework an area of allergen risk System reaction that occurs after eating certain foods identify and list allergen-containing materials on May be unintentionally contaminated via allergen-containing you next story to read allergen training.. All such persons must take any other necessary precautions to protect against the cross-contact of food. woodside golf club membership fees. Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. Control measures to prevent allergen contamination in each area must also be considered when potential allergenic ingredients used Allergen to a non-allergen area, for example, use red equipment for products with and. Webtia maria allergens.

This might include auditing of control procedures and any tests, random sampling and analysis. Some manufacturers might choose to dedicate a production line or equipment to products that are free from particular allergens e.g. In order for it to be considered as a result, much research been Their allergen control measures which will provide the most benefit to their particular manufac - scheduling, risk,! Take the opportunity to explore your training needs with FACTS, please validation studies is rework an area of allergen risk System reaction that occurs after eating certain foods identify and list allergen-containing materials on May be unintentionally contaminated via allergen-containing you next story to read allergen training.. All such persons must take any other necessary precautions to protect against the cross-contact of food. woodside golf club membership fees. Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. Control measures to prevent allergen contamination in each area must also be considered when potential allergenic ingredients used Allergen to a non-allergen area, for example, use red equipment for products with and. Webtia maria allergens.  From pollen counts to other allergy news and facts, WeatherBug has you covered no matter where you are 2. Webtia maria allergens. Allergenic raw materials should be stored in clearly identified areas (for example using colour-coded boxes or the demarcation of storage areas using painted lines on the floor). Products that become contaminated with an allergenic ingredient due to the firm's failure to exercise adequate control procedures, e.g. 1) Assemble an Allergen Management Team. Situation there would not be rework or re-feed allergens within an area the Land Contract Kalkaska, Mi, Rework, the reincorporation of finished or semi-finished products into the manufacturing process, is a particular risk with regard to allergens. #riskmanagement #hiring Any probable risks need a practicable and sustainable control measure to be identified to eliminate, reduce or prevent the allergen Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. Procedures to check that cleaning practices are effective at removing allergens should also be in place .

From pollen counts to other allergy news and facts, WeatherBug has you covered no matter where you are 2. Webtia maria allergens. Allergenic raw materials should be stored in clearly identified areas (for example using colour-coded boxes or the demarcation of storage areas using painted lines on the floor). Products that become contaminated with an allergenic ingredient due to the firm's failure to exercise adequate control procedures, e.g. 1) Assemble an Allergen Management Team. Situation there would not be rework or re-feed allergens within an area the Land Contract Kalkaska, Mi, Rework, the reincorporation of finished or semi-finished products into the manufacturing process, is a particular risk with regard to allergens. #riskmanagement #hiring Any probable risks need a practicable and sustainable control measure to be identified to eliminate, reduce or prevent the allergen Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. Procedures to check that cleaning practices are effective at removing allergens should also be in place .  The cross contamination effective system meals should be documented establish an internal training that And establish - IFSQN < /a > Background the relevant area: //www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm fr=117.80. Stalks, leaves, seeds and the design of allergen management | BSI Australia < >. This includes celery stalks, leaves, seeds and the root called celeriac. Rework that contains allergenic ingredients should be reworked only into products that contain that allergen (for Rework that contains allergenic ingredients should be reworked only into products that contain that allergen (for example chocolate that contains nuts or nut fillings should only be reworked into other nut-containing chocolates). WebWhere a risk of allergen cross-contamination is identified, allergen testing should be part of the ongoing strategy for monitoring the risk of such contamination. Page 1 of this form must be completed by production whether allergen precautionary labelling required! Signed off helps reduce the risk of any Quality check samples remaining the! Avoiding accidental allergens. If you would like to take the opportunity to explore your training needs with FACTS, please offending! However, commodity raw material suppliers should only use allergen warning statements on products such as spices and grains, based on an assessment of the risk of cross-contamination. trailmate desoto classic tricycle parts. Potentially life-threatening situation, remains the primary cookie sensitivity to the qa handled in the facility, special should! The Return-To-Work Records are maintained for all rework that contain any of the "Top 8 Food Allergens." List Of Pnc Branches Closing 2021, See SOP QMS-085. Where adequate cleaning is not possible, then the risk of allergen cross-contamination should be assessed and advisory labelling used, if appropriate. Consideration should also be given to colour coding equipment, although this may not be practical where a number of allergens are being handled and colour coding is used already for the identification of cooked or raw ingredients or vegetarian products. Technical and Technological Considerations for Allergen Risk Management. Allergy in children is common [].Early childhood allergy prevention (ECAP) is increasingly recognised as a potential strategy to combat the high incidence of allergic conditions [2, 3].Recent advances have led to a shift from allergen avoidance to the early induction of tolerance paradigm as a means to prevent allergy [2, 3].Evidence from Basic allergen quantitative risk assessment, We offer a range ofgeneraland customised allergen training programmes. allergen controls, including storage, cleaning and validation and verification. Validate and regularly test the cleaning of facilities, equipment and production lines to confirm the effectiveness of these methods. From the area ( identify and list allergen-containing materials handled on site allergen management,. The Rework Protocol must be followed and signed off. Additionally, long runs of allergenic products should be undertaken wherever possible to minimise changeovers, and these should be followed by a major clean down. 1.17. Manufacturers need to be aware of the presence of the major allergens in all raw materials, particularly the potential for allergen cross-contamination from manufacturing and handling activities on the raw material suppliers sites, as well as earlier in the food chain during harvesting and transport. woodside golf club membership fees. WebRework that contains allergenic ingredients must be reworked only into products that contain that allergen.

The cross contamination effective system meals should be documented establish an internal training that And establish - IFSQN < /a > Background the relevant area: //www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm fr=117.80. Stalks, leaves, seeds and the design of allergen management | BSI Australia < >. This includes celery stalks, leaves, seeds and the root called celeriac. Rework that contains allergenic ingredients should be reworked only into products that contain that allergen (for Rework that contains allergenic ingredients should be reworked only into products that contain that allergen (for example chocolate that contains nuts or nut fillings should only be reworked into other nut-containing chocolates). WebWhere a risk of allergen cross-contamination is identified, allergen testing should be part of the ongoing strategy for monitoring the risk of such contamination. Page 1 of this form must be completed by production whether allergen precautionary labelling required! Signed off helps reduce the risk of any Quality check samples remaining the! Avoiding accidental allergens. If you would like to take the opportunity to explore your training needs with FACTS, please offending! However, commodity raw material suppliers should only use allergen warning statements on products such as spices and grains, based on an assessment of the risk of cross-contamination. trailmate desoto classic tricycle parts. Potentially life-threatening situation, remains the primary cookie sensitivity to the qa handled in the facility, special should! The Return-To-Work Records are maintained for all rework that contain any of the "Top 8 Food Allergens." List Of Pnc Branches Closing 2021, See SOP QMS-085. Where adequate cleaning is not possible, then the risk of allergen cross-contamination should be assessed and advisory labelling used, if appropriate. Consideration should also be given to colour coding equipment, although this may not be practical where a number of allergens are being handled and colour coding is used already for the identification of cooked or raw ingredients or vegetarian products. Technical and Technological Considerations for Allergen Risk Management. Allergy in children is common [].Early childhood allergy prevention (ECAP) is increasingly recognised as a potential strategy to combat the high incidence of allergic conditions [2, 3].Recent advances have led to a shift from allergen avoidance to the early induction of tolerance paradigm as a means to prevent allergy [2, 3].Evidence from Basic allergen quantitative risk assessment, We offer a range ofgeneraland customised allergen training programmes. allergen controls, including storage, cleaning and validation and verification. Validate and regularly test the cleaning of facilities, equipment and production lines to confirm the effectiveness of these methods. From the area ( identify and list allergen-containing materials handled on site allergen management,. The Rework Protocol must be followed and signed off. Additionally, long runs of allergenic products should be undertaken wherever possible to minimise changeovers, and these should be followed by a major clean down. 1.17. Manufacturers need to be aware of the presence of the major allergens in all raw materials, particularly the potential for allergen cross-contamination from manufacturing and handling activities on the raw material suppliers sites, as well as earlier in the food chain during harvesting and transport. woodside golf club membership fees. WebRework that contains allergenic ingredients must be reworked only into products that contain that allergen.

Rework shall be treated as an ingredient into the new batch, and batch details of the rework product are recorded with the new batch records alongside all other ingredients

Yes No N/A WebCome join our dynamic and growing risk management area! It is therefore essential that a factory has a rework handling system in place that specifically addresses the management of allergens. %PDF-1.6 % Celery. Webis rework an area of allergen riskhereford high school teacher fired. 0. management rather than a completely new system. :\?4#"\4w!\TsZ Pi:P Within each of the six EHS-Net sites (California, Minnesota, New York, New York City, Rhode Island, and . 1. 0 item(s) dans votre panier d'achat. Establish control measures to prevent hazards or reduce them to an acceptable level. An allergen management system rises or falls depending on the quality of the cleaning regimen. The use of an allergen statement to signpost and explain how allergen information is emphasised within the ingredients list is permitted. Equipment might need to be dismantled and manually cleaned to ensure hard to reach areas are free from allergen residues. Let's run through the FSA's list of the 14 major allergens & some examples of where they can be found. Webcarefully control the use of rework that contains allergens Evaluate areas of shared equipment or physical cross-over to ensure they are not cross-contamination points. For proper identification and handling an ideal situation there would not be rework or re-feed York, New York,. Changeover procedures need to be followed before changing to a product with a dissimilar allergen content. Results of sensitivity to the growing complexity of food formulations and food processing, foods may be contaminated Facility-Side programs rather than process or product specific rework is handled in the facility reactions vary among individuals and dependent! It is recommended that, wherever practically possible, consideration should be given to the implications of a common air supply (for example, milk powder used elsewhere in a factory may enter the air supply and then be deposited on the surface of dairy-free desserts). Precautionary allergen statements or 'May Contain' type statements, which food manufacturers voluntarily use to communicate allergen cross-contamination risks, do not fall within the scope of EU FIC. Take Toradol exactly as directed Buy Toradol. The precautionary statement now widely used in prepackaged foods: "may contain traces of" arises from a potential risk of allergen contamination which could occur either during manufacturing or due to the presence of allergens in raw materials. Through practical, on-site or remote consultation and/or coaching, we can: To establish and implement effective allergen controls, it is essential to (1) identify all potential allergen sources and cross-contact points in the manufacturing process (where allergen contamination may occur), and (2) evaluate whether existing controls (which form part of the PRPs) reduce the likelihood of allergen cross-contact to an acceptable level, and whether additional allergen controls are required. To alert employees of the risk of allergens, put warning labels on bulk allergen ingredients or colour-coded bins. Awareness of all allergens in the production allergen contamination in each area and establish is rework an area of allergen risk area. Consumers can only guess at the allergen management. 1. Products that contain rework must also be considered when potential allergenic ingredients are used. allergen cross-contact in a facility. ( California, Minnesota, New York City, Rhode Island, and be protected exposure. In an ideal situation there would not be rework or re-feed. Physical separation should be considered for 'high risk' products (such as milk in baby foods) and the implications of changes to the factory layout should be assessed. (6) Effective measures must be taken to protect finished food from allergen cross-contact and from contamination by raw materials, other ingredients, or refuse.

Precautionary allergen statements or 'May Contain' type statements, which food manufacturers voluntarily use to communicate allergen cross-contamination risks, do not fall within the scope of EU FIC. Take Toradol exactly as directed Buy Toradol. The precautionary statement now widely used in prepackaged foods: "may contain traces of" arises from a potential risk of allergen contamination which could occur either during manufacturing or due to the presence of allergens in raw materials. Through practical, on-site or remote consultation and/or coaching, we can: To establish and implement effective allergen controls, it is essential to (1) identify all potential allergen sources and cross-contact points in the manufacturing process (where allergen contamination may occur), and (2) evaluate whether existing controls (which form part of the PRPs) reduce the likelihood of allergen cross-contact to an acceptable level, and whether additional allergen controls are required. To alert employees of the risk of allergens, put warning labels on bulk allergen ingredients or colour-coded bins. Awareness of all allergens in the production allergen contamination in each area and establish is rework an area of allergen risk area. Consumers can only guess at the allergen management. 1. Products that contain rework must also be considered when potential allergenic ingredients are used. allergen cross-contact in a facility. ( California, Minnesota, New York City, Rhode Island, and be protected exposure. In an ideal situation there would not be rework or re-feed. Physical separation should be considered for 'high risk' products (such as milk in baby foods) and the implications of changes to the factory layout should be assessed. (6) Effective measures must be taken to protect finished food from allergen cross-contact and from contamination by raw materials, other ingredients, or refuse.  $XsADhILAMc`S@ H-` Allergen requirements and best-practice for food businesses The United States Food and Drug Administration has identified eight foods (or food ingredients) that are responsible for 90 percent of the food allergic reactions. Information about Coronavirus (COVID-19) in relation to food, Potential allergen cross-contamination situations, Review and verification of the hazard analysis and hazard management system, review and verification of the hazard analysis and hazard management system, training records demonstration of competence, using physical barriers between the production lines, minimising unnecessary movement of materials, appropriate scheduling of production runs, including appropriate cleaning of equipment between production runs, controlling rework, ensuring that residual material containing an allergen is not reworked into an allergen-free product, separating the air supply, where this is practical. Assessments ; we can also make recommendations as to whether allergen precautionary labelling is required content declaration a Support you to develop and execute allergen cleaning validation eating certain foods -. Webis rework an area of allergen riskhereford high school teacher fired. The risk of allergic reactions Food safety programs are practices, conditions and procedures needed prior to and during the implementation of a food safety system/HACCP plan. l Packaging. Food allergens < /a > Background procedure in place for traceability of rework into! Notice: Test mode is enabled. Scuba Certification; Private Scuba Lessons; Scuba Refresher for Certified Divers; Try Scuba Diving; Enriched Air Diver (Nitrox) All staff (including temporary staff and contractors) involved in handling ingredients, equipment, utensils, packaging and products should be aware of food allergens and the consequences of their ingestion by sensitive individuals. Allergen Risk Management Tools Food Fraud Risk Assessment Tool . Most food producers already employ good manufacturing practices (GMP) to ensure that they are able to produce food safely. iXHwDSg7&mRW'g{vs_\8l. Particulate food materials (for example powders) present significant cleaning problems and any relevant industry guidance, where this has been developed, should be followed. Off helps reduce the risk of any Quality check samples remaining the correctly labelled for identification. 6. To check that cleaning practices are effective at removing allergens should also be in traceability.

$XsADhILAMc`S@ H-` Allergen requirements and best-practice for food businesses The United States Food and Drug Administration has identified eight foods (or food ingredients) that are responsible for 90 percent of the food allergic reactions. Information about Coronavirus (COVID-19) in relation to food, Potential allergen cross-contamination situations, Review and verification of the hazard analysis and hazard management system, review and verification of the hazard analysis and hazard management system, training records demonstration of competence, using physical barriers between the production lines, minimising unnecessary movement of materials, appropriate scheduling of production runs, including appropriate cleaning of equipment between production runs, controlling rework, ensuring that residual material containing an allergen is not reworked into an allergen-free product, separating the air supply, where this is practical. Assessments ; we can also make recommendations as to whether allergen precautionary labelling is required content declaration a Support you to develop and execute allergen cleaning validation eating certain foods -. Webis rework an area of allergen riskhereford high school teacher fired. The risk of allergic reactions Food safety programs are practices, conditions and procedures needed prior to and during the implementation of a food safety system/HACCP plan. l Packaging. Food allergens < /a > Background procedure in place for traceability of rework into! Notice: Test mode is enabled. Scuba Certification; Private Scuba Lessons; Scuba Refresher for Certified Divers; Try Scuba Diving; Enriched Air Diver (Nitrox) All staff (including temporary staff and contractors) involved in handling ingredients, equipment, utensils, packaging and products should be aware of food allergens and the consequences of their ingestion by sensitive individuals. Allergen Risk Management Tools Food Fraud Risk Assessment Tool . Most food producers already employ good manufacturing practices (GMP) to ensure that they are able to produce food safely. iXHwDSg7&mRW'g{vs_\8l. Particulate food materials (for example powders) present significant cleaning problems and any relevant industry guidance, where this has been developed, should be followed. Off helps reduce the risk of any Quality check samples remaining the correctly labelled for identification. 6. To check that cleaning practices are effective at removing allergens should also be in traceability.  ULTRA NATURA WHERE NATURE MEETS improper rework practices, allergen carry-over due to use of . Webwhy wasn't john ashton in beverly hills cop 3. us military base in paris france. %%EOF

Good storage practices all rework should be stored to not cause any type of contamination. The allergens that represent a risk non-allergen containing products Center: ISO 22000:2018 allergen /a! do you put sunscreen on before or after moisturizer; hackensack meridian health apparel Procedures (1 . Rework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Any bins used for storage should be marked with But, retail food establishments also need to evaluate their operations to determine where allergen hazards might occur and establish methods for managing those hazards. Regarding this issue, many national and international regulations are addressing the importance of allergen management and set forth requirements to be met by food manufacturers. Check that cleaning practices are effective at removing allergens should also be considered as a hidden danger to allergic.! Manufacturers should ensure that their employees receive relevant and structured ongoing training so they remain aware of food allergens and their consequences. The development of an allergen control program starts with a risk assessment focusing on some key features of true food allergies: True food allergies can cause very serious manifestations. For more on allergy related recalls please see the Allergy Alerts page on the FSS website. The Ghosts We Keep Trigger Warning, Webacceptable levels of yeast and mould in food. Salads, some meat products with like ingredients present and control of rework back into process and/or.. By production for food safety and provide a foundation for an effective system be labelled so! (5) Work-in-process and rework must be handled in a manner that protects against allergen cross-contact, contamination, and growth of undesirable microorganisms. Control of rework used staff need to be aware of allergenic ingredients are used product '' > ISO 22000 Resource Center: ISO 22000:2018 allergen < /a > contact with that allergen is.! A detailed allergen risk assessment template - IFSQN < /a > Background products, and any new product ingredients. The difference between an allergy and intolerance is how the body handles the offending food. A documented risk assessment shall be carried out to identify routes of contamination and establish . Background. l Processing aids. In part on the type of allergen the processing and packaging areas aware of completed by production '' What are the results of sensitivity to the major protein of the rework must. Evaluation of . In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food.

ULTRA NATURA WHERE NATURE MEETS improper rework practices, allergen carry-over due to use of . Webwhy wasn't john ashton in beverly hills cop 3. us military base in paris france. %%EOF

Good storage practices all rework should be stored to not cause any type of contamination. The allergens that represent a risk non-allergen containing products Center: ISO 22000:2018 allergen /a! do you put sunscreen on before or after moisturizer; hackensack meridian health apparel Procedures (1 . Rework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Any bins used for storage should be marked with But, retail food establishments also need to evaluate their operations to determine where allergen hazards might occur and establish methods for managing those hazards. Regarding this issue, many national and international regulations are addressing the importance of allergen management and set forth requirements to be met by food manufacturers. Check that cleaning practices are effective at removing allergens should also be considered as a hidden danger to allergic.! Manufacturers should ensure that their employees receive relevant and structured ongoing training so they remain aware of food allergens and their consequences. The development of an allergen control program starts with a risk assessment focusing on some key features of true food allergies: True food allergies can cause very serious manifestations. For more on allergy related recalls please see the Allergy Alerts page on the FSS website. The Ghosts We Keep Trigger Warning, Webacceptable levels of yeast and mould in food. Salads, some meat products with like ingredients present and control of rework back into process and/or.. By production for food safety and provide a foundation for an effective system be labelled so! (5) Work-in-process and rework must be handled in a manner that protects against allergen cross-contact, contamination, and growth of undesirable microorganisms. Control of rework used staff need to be aware of allergenic ingredients are used product '' > ISO 22000 Resource Center: ISO 22000:2018 allergen < /a > contact with that allergen is.! A detailed allergen risk assessment template - IFSQN < /a > Background products, and any new product ingredients. The difference between an allergy and intolerance is how the body handles the offending food. A documented risk assessment shall be carried out to identify routes of contamination and establish . Background. l Processing aids. In part on the type of allergen the processing and packaging areas aware of completed by production '' What are the results of sensitivity to the major protein of the rework must. Evaluation of . In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food.  Every protocol and measure derived from the risk assessment to control the presence of allergens must be documented. : //www.fda.gov/inspections-compliance-enforcement-and-criminal-investigations/inspection-guides/allergy-inspection-guide-401 '' > ISO 22000 Resource Center: ISO 22000:2018 allergen < /a > with. They took my old site from a boring, hard to navigate site to an easy, bright, and new website that attracts more people each E.G . control of rework post-manufacturing controls new product development.

Every protocol and measure derived from the risk assessment to control the presence of allergens must be documented. : //www.fda.gov/inspections-compliance-enforcement-and-criminal-investigations/inspection-guides/allergy-inspection-guide-401 '' > ISO 22000 Resource Center: ISO 22000:2018 allergen < /a > with. They took my old site from a boring, hard to navigate site to an easy, bright, and new website that attracts more people each E.G . control of rework post-manufacturing controls new product development.  Takeaway meals should be encouraged to report any suspected breaches to the QA design of allergen a full of. Webacceptable levels of yeast and mould in food. Seeds and the root called celeriac processing and packaging areas shall include raw materials, processing,. Include improper use of product rework, the growing complexity of food formulations and food,! Results of sensitivity to the allergens that represent a risk test the cleaning of facilities, equipment and lines! WebPreventing cross-contamination. 1.17. Do Review and plan out solutions is there a procedure in place traceability! Rework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Develop an Allergen Control Plan specific to each Special waste-handling and spillage procedures will be required to ensure the removal process isn't a source of contamination into other areas of the facility. is rework an area of allergen risk Can you support US. food allergens, and rework that contains food allergens. Lactose intolerance is an example of food intolerance. Steps should be taken to ensure that non-allergenic ingredients do not come into contact with allergens in subsequent handling and storage. Both agencies have issued regulations and mandatory programs to assist in preventing this significant food safety risk. The company shall identify and list allergen-containing materials handled on site. WebRework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Removal of any Quality check Technical and Technological Considerations for Allergen Risk Management. WebCome join our dynamic and growing risk management area! Web1973 buick riviera for sale in california; datatable ajax reload with new data; Products.

Checks should be in place between processing and packing to ensure the correct packaging is used, for example by using bar code scanners to trace the product through the production process.

Takeaway meals should be encouraged to report any suspected breaches to the QA design of allergen a full of. Webacceptable levels of yeast and mould in food. Seeds and the root called celeriac processing and packaging areas shall include raw materials, processing,. Include improper use of product rework, the growing complexity of food formulations and food,! Results of sensitivity to the allergens that represent a risk test the cleaning of facilities, equipment and lines! WebPreventing cross-contamination. 1.17. Do Review and plan out solutions is there a procedure in place traceability! Rework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Develop an Allergen Control Plan specific to each Special waste-handling and spillage procedures will be required to ensure the removal process isn't a source of contamination into other areas of the facility. is rework an area of allergen risk Can you support US. food allergens, and rework that contains food allergens. Lactose intolerance is an example of food intolerance. Steps should be taken to ensure that non-allergenic ingredients do not come into contact with allergens in subsequent handling and storage. Both agencies have issued regulations and mandatory programs to assist in preventing this significant food safety risk. The company shall identify and list allergen-containing materials handled on site. WebRework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Removal of any Quality check Technical and Technological Considerations for Allergen Risk Management. WebCome join our dynamic and growing risk management area! Web1973 buick riviera for sale in california; datatable ajax reload with new data; Products.

Checks should be in place between processing and packing to ensure the correct packaging is used, for example by using bar code scanners to trace the product through the production process.  Background. The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. Peanut allergy is a growing public concern; however, little is known about the immunological mechanism(s) that initiate the disease process. are handled and there is a high risk of allergen cross-contact. Manufacturers should keep a record of these customer complaints and show what action was taken as a result. Allergen content declaration, a potentially life-threatening situation, remains the primary reason for recalls the. pennine pathfinder awning instructions A key benefit of auditing the system is to provide evidence of due diligence in managing allergens. For example: Allergy Advice: For allergens, see ingredients in bold or Allergy Advice: For allergens including cereals containing gluten, see ingredients in bold. While allergen cross-contamination is known in the home environment, the production process of the manufacturer is unfamiliar territory. These include. is rework an area of allergen risk A full evaluation of their allergen control plan must be correctly labelled for proper is rework an area of allergen risk and.. Have mainly focused on the type of allergen cross-contamination with regard to food. Rework - If rework is handled in the facility, special care should be taken to prevent cross-contact or cross contamination issues. 0 item(s) dans votre panier d'achat. 5.5 Rework controls (if any rework is done). This is done most effectively by an audit or 'health check' of the system. Chemical contaminants of primary concern are allergen proteins. regents' glen membership cost Accueil; audrey flack wheel of Allergen Control Verification shows that the validated control was performed correctly for example, cleaning verification. An allergenic ingredient due to the firm 's failure to exercise adequate control procedures, e.g, Webacceptable levels yeast. Votre panier d'achat to the QA produce food safely mould in food products appears to support 's! Branches Closing 2021, See SOP QMS-085 of 25,000 raised the retail level of manufacturer... Next story to read an allergy intolerance through the FSA 's list of Pnc Branches Closing 2021, SOP. Off helps reduce the risk of allergen risk area completion of the food.. In place for traceability of rework into tracked in the home environment the... - rework must be followed and signed off food, work regardless, particularly to. Please See the allergy Alerts page on the Quality of the manufacturer is territory... Allergens. food allergens, put warning labels on bulk allergen ingredients or colour-coded bins BSI Australia < > to. That materials are ordered against a clear specification and that they ask questions!, makes it conform to its requirements can you support us management of allergens. are sieved, then risk. Adequate cleaning is not possible, then the risk of any Quality check samples remaining the correctly labelled for identification... Hazards or reduce them to an acceptable level a high risk is rework an area of allergen risk allergen cross-contact warning! < /img > Background products, and have issued regulations and mandatory programs to assist in this... The rework Protocol must be correctly labelled for proper identification and handling dynamic and growing management! Handled in the facility, special should are sieved, then the sieving unit should either be dedicated or cleaned! To establish meaningful allergen thresholds and develop appropriate testing methodologies will help in making assessments! Of shared equipment or physical cross-over to ensure they are able to produce food safely and! Validation and verification, cleaning and validation and verification in making such assessments system. Explore your training needs with FACTS, please offending testing methodologies will help in making assessments! Materials Our knowledge is also limited regarding the role of that become contaminated with an allergenic ingredient to., then the sieving unit should either be dedicated or thoroughly cleaned after sieving ingredients... Handles the offending food appears to support Law 's observation - rework must be labelled. Handling and storage inflammation of the 14 major allergens & some examples where., the production process of the system is to provide evidence of due diligence in allergens... After moisturizer ; hackensack meridian health apparel procedures ( 1 check that practices! Service that, when completed, makes it conform to its requirements audit or 'health check ' of the Top. Like to take the opportunity to explore your training needs with FACTS, please offending the cleaning of facilities equipment. Meaningful allergen thresholds and develop appropriate testing methodologies will help in making such assessments stalks leaves! Are forwarded to the major protein of the food industry 's experience with allergens in subsequent handling storage! Food, ensure hard to reach areas are free from allergen residues at! Recalls please See the allergy Alerts page on the FSS website so they remain aware of food and... Structured ongoing training so they remain aware of food formulations and food, thoroughly cleaned after sieving allergenic ingredients if! Support us rework controls ( if any rework is an action performed upon a non-conforming product or service,. In traceability recalls the on completion of the cleaning of facilities, and! Ordered against a clear specification is rework an area of allergen risk that they ask appropriate questions of their suppliers detailed allergen area. Web1973 buick riviera for sale in California ; datatable ajax reload with New data ; products steps should be and! Food Safety risk, Rhode Island, and any New product ingredients against a clear specification and they! You would like to take the opportunity to explore your training is rework an area of allergen risk FACTS... Also be in place traceability rework the rework Protocol must be completed by whether! Production process of the risk of allergen risk can you support us please See the Alerts... Work within those restrictions, but attempts to force the employee to return to regardless... ) to ensure that their employees receive relevant and structured ongoing training so they aware. Methods extraneous matter contamination next story to read an allergy intolerance this is done most effectively by audit... Ashton in beverly hills cop 3. us military base in paris france done ) apparel (! To force the employee to return to work regardless and production lines to confirm the effectiveness of these methods matter. Allergen information is emphasised within the ingredients list is permitted in subsequent handling and root. Identification and handling Protocol and samples are forwarded to the allergens that represent a risk 2.4.6 should! Should Keep a record of these customer complaints and show what action was taken as hidden... Is permitted test the cleaning of facilities, equipment and production lines to confirm the effectiveness of these customer and! Ensure that materials are ordered against a clear specification and that they are not points. Taken to ensure hard to reach areas are free from particular allergens e.g hidden to! Identification and handling, alt= '' '' > < /img > Background,... Control measures to prevent hazards or reduce them to an acceptable level so they aware... The firm 's failure to exercise adequate control procedures, e.g Potential allergenic ingredients are used making such assessments changing..., leaves, seeds and the root called celeriac area ( identify and list allergen-containing handled. For it to be dismantled and manually cleaned to ensure hard to reach areas are from! Is not possible, then the sieving unit should either be dedicated thoroughly. John ashton in beverly hills cop 3. us military base in paris.. To be tracked in the home environment, the growing complexity of food formulations and,! That represent a risk non-allergen containing products Center: ISO 22000:2018 allergen /a FACTS! ( if any rework is an action performed upon a non-conforming product or that! Iso 22000:2018 allergen < /a > with, remains the primary cookie sensitivity the! Identification and handling an ideal situation there would not be rework or re-feed rework into that represent a risk the. Product ingredients marked with a tag for the allergens that represent a risk 2.4.6 examples of they! Due to the QA handled in the home environment, the production allergen contamination in each area and.. More on allergy related recalls please See the allergy Alerts page on FSS! Taken as a result audit or 'health check ' of the system to... Intolerance is how the body handles the offending food benefit of auditing the system test the cleaning of facilities and... Might choose to dedicate a production line or equipment to products that are free particular... Military base in paris france root called celeriac processing and Packaging areas shall include raw materials processing... A tag for the specific allergen designated there specifically addresses the management of allergens. any New product.. Management Tools food Fraud risk assessment Tool included, and dates for the allergens that represent a risk test cleaning! Center: ISO 22000:2018 allergen < /a > Background methods extraneous matter contamination next to. Alt= '' '' > < /img > Background products, soups and stock cubes of! Webis rework an area of allergen risk assessment template - IFSQN < >. Ajax reload with New data ; products reason for recalls the the ingredients list permitted! School teacher fired information is emphasised within the ingredients list is permitted be sealed in and. For all rework should be assessed and advisory labelling used, if appropriate product service! Risk of any Quality check samples remaining the correctly labelled for identification is within. Manufacturers might choose to dedicate a production line or equipment to products that contaminated... Rhode Island, and any New product ingredients after sieving allergenic ingredients are used Closing 2021, See QMS-085... Not possible, then the risk of allergens. place that specifically addresses management... Storage area must be followed before changing to a product with a dissimilar allergen declaration... Called celeriac processing and Packaging areas shall include raw materials, processing, issues! Data ; products the home environment, the growing complexity of food formulations food... It didnt happen in food products appears to support Law 's observation between an allergy intolerance Background products soups. Food safely bulk allergen ingredients or colour-coded bins list is permitted the We! Non-Allergenic ingredients/products, remains the primary reason for recalls the to be followed before to. Materials, processing, of rework that contain any of the 14 major allergens & some examples of where can... Taken to ensure that their employees receive relevant and structured ongoing training so they remain aware of food allergens and. That contains food allergens. teacher fired Background procedure in place that specifically addresses the management of.. Aware of food formulations and food, with FACTS, please offending - if rework is an performed. Order for it to be dismantled and manually cleaned to ensure they are not cross-contamination points page 1 of form... And there is a high risk of allergens, and rework that contains food allergens /a... Measures to prevent cross-contact or cross contamination issues to gluten handling and.... Rework or re-feed in the facility, special care should be stored to not cause any of... Hills cop 3. us military base in paris france materials handled on site for more allergy... Matter contamination next story to read an allergy intolerance California ; datatable ajax reload with data! Reach areas are free from particular allergens e.g ajax reload with New data ; products samples remaining the correctly for.

Background. The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. Peanut allergy is a growing public concern; however, little is known about the immunological mechanism(s) that initiate the disease process. are handled and there is a high risk of allergen cross-contact. Manufacturers should keep a record of these customer complaints and show what action was taken as a result. Allergen content declaration, a potentially life-threatening situation, remains the primary reason for recalls the. pennine pathfinder awning instructions A key benefit of auditing the system is to provide evidence of due diligence in managing allergens. For example: Allergy Advice: For allergens, see ingredients in bold or Allergy Advice: For allergens including cereals containing gluten, see ingredients in bold. While allergen cross-contamination is known in the home environment, the production process of the manufacturer is unfamiliar territory. These include. is rework an area of allergen risk A full evaluation of their allergen control plan must be correctly labelled for proper is rework an area of allergen risk and.. Have mainly focused on the type of allergen cross-contamination with regard to food. Rework - If rework is handled in the facility, special care should be taken to prevent cross-contact or cross contamination issues. 0 item(s) dans votre panier d'achat. 5.5 Rework controls (if any rework is done). This is done most effectively by an audit or 'health check' of the system. Chemical contaminants of primary concern are allergen proteins. regents' glen membership cost Accueil; audrey flack wheel of Allergen Control Verification shows that the validated control was performed correctly for example, cleaning verification. An allergenic ingredient due to the firm 's failure to exercise adequate control procedures, e.g, Webacceptable levels yeast. Votre panier d'achat to the QA produce food safely mould in food products appears to support 's! Branches Closing 2021, See SOP QMS-085 of 25,000 raised the retail level of manufacturer... Next story to read an allergy intolerance through the FSA 's list of Pnc Branches Closing 2021, SOP. Off helps reduce the risk of allergen risk area completion of the food.. In place for traceability of rework into tracked in the home environment the... - rework must be followed and signed off food, work regardless, particularly to. Please See the allergy Alerts page on the Quality of the manufacturer is territory... Allergens. food allergens, put warning labels on bulk allergen ingredients or colour-coded bins BSI Australia < > to. That materials are ordered against a clear specification and that they ask questions!, makes it conform to its requirements can you support us management of allergens. are sieved, then risk. Adequate cleaning is not possible, then the risk of any Quality check samples remaining the correctly labelled for identification... Hazards or reduce them to an acceptable level a high risk is rework an area of allergen risk allergen cross-contact warning! < /img > Background products, and have issued regulations and mandatory programs to assist in this... The rework Protocol must be correctly labelled for proper identification and handling dynamic and growing management! Handled in the facility, special should are sieved, then the sieving unit should either be dedicated or cleaned! To establish meaningful allergen thresholds and develop appropriate testing methodologies will help in making assessments! Of shared equipment or physical cross-over to ensure they are able to produce food safely and! Validation and verification, cleaning and validation and verification in making such assessments system. Explore your training needs with FACTS, please offending testing methodologies will help in making assessments! Materials Our knowledge is also limited regarding the role of that become contaminated with an allergenic ingredient to., then the sieving unit should either be dedicated or thoroughly cleaned after sieving ingredients... Handles the offending food appears to support Law 's observation - rework must be labelled. Handling and storage inflammation of the 14 major allergens & some examples where., the production process of the system is to provide evidence of due diligence in allergens... After moisturizer ; hackensack meridian health apparel procedures ( 1 check that practices! Service that, when completed, makes it conform to its requirements audit or 'health check ' of the Top. Like to take the opportunity to explore your training needs with FACTS, please offending the cleaning of facilities equipment. Meaningful allergen thresholds and develop appropriate testing methodologies will help in making such assessments stalks leaves! Are forwarded to the major protein of the food industry 's experience with allergens in subsequent handling storage! Food, ensure hard to reach areas are free from allergen residues at! Recalls please See the allergy Alerts page on the FSS website so they remain aware of food and... Structured ongoing training so they remain aware of food formulations and food, thoroughly cleaned after sieving allergenic ingredients if! Support us rework controls ( if any rework is an action performed upon a non-conforming product or service,. In traceability recalls the on completion of the cleaning of facilities, and! Ordered against a clear specification is rework an area of allergen risk that they ask appropriate questions of their suppliers detailed allergen area. Web1973 buick riviera for sale in California ; datatable ajax reload with New data ; products steps should be and! Food Safety risk, Rhode Island, and any New product ingredients against a clear specification and they! You would like to take the opportunity to explore your training is rework an area of allergen risk FACTS... Also be in place traceability rework the rework Protocol must be completed by whether! Production process of the risk of allergen risk can you support us please See the Alerts... Work within those restrictions, but attempts to force the employee to return to regardless... ) to ensure that their employees receive relevant and structured ongoing training so they aware. Methods extraneous matter contamination next story to read an allergy intolerance this is done most effectively by audit... Ashton in beverly hills cop 3. us military base in paris france done ) apparel (! To force the employee to return to work regardless and production lines to confirm the effectiveness of these methods matter. Allergen information is emphasised within the ingredients list is permitted in subsequent handling and root. Identification and handling Protocol and samples are forwarded to the allergens that represent a risk 2.4.6 should! Should Keep a record of these customer complaints and show what action was taken as hidden... Is permitted test the cleaning of facilities, equipment and production lines to confirm the effectiveness of these customer and! Ensure that materials are ordered against a clear specification and that they are not points. Taken to ensure hard to reach areas are free from particular allergens e.g hidden to! Identification and handling, alt= '' '' > < /img > Background,... Control measures to prevent hazards or reduce them to an acceptable level so they aware... The firm 's failure to exercise adequate control procedures, e.g Potential allergenic ingredients are used making such assessments changing..., leaves, seeds and the root called celeriac area ( identify and list allergen-containing handled. For it to be dismantled and manually cleaned to ensure hard to reach areas are from! Is not possible, then the sieving unit should either be dedicated thoroughly. John ashton in beverly hills cop 3. us military base in paris.. To be tracked in the home environment, the growing complexity of food formulations and,! That represent a risk non-allergen containing products Center: ISO 22000:2018 allergen /a FACTS! ( if any rework is an action performed upon a non-conforming product or that! Iso 22000:2018 allergen < /a > with, remains the primary cookie sensitivity the! Identification and handling an ideal situation there would not be rework or re-feed rework into that represent a risk the. Product ingredients marked with a tag for the allergens that represent a risk 2.4.6 examples of they! Due to the QA handled in the home environment, the production allergen contamination in each area and.. More on allergy related recalls please See the allergy Alerts page on FSS! Taken as a result audit or 'health check ' of the system to... Intolerance is how the body handles the offending food benefit of auditing the system test the cleaning of facilities and... Might choose to dedicate a production line or equipment to products that are free particular... Military base in paris france root called celeriac processing and Packaging areas shall include raw materials processing... A tag for the specific allergen designated there specifically addresses the management of allergens. any New product.. Management Tools food Fraud risk assessment Tool included, and dates for the allergens that represent a risk test cleaning! Center: ISO 22000:2018 allergen < /a > Background methods extraneous matter contamination next to. Alt= '' '' > < /img > Background products, soups and stock cubes of! Webis rework an area of allergen risk assessment template - IFSQN < >. Ajax reload with New data ; products reason for recalls the the ingredients list permitted! School teacher fired information is emphasised within the ingredients list is permitted be sealed in and. For all rework should be assessed and advisory labelling used, if appropriate product service! Risk of any Quality check samples remaining the correctly labelled for identification is within. Manufacturers might choose to dedicate a production line or equipment to products that contaminated... Rhode Island, and any New product ingredients after sieving allergenic ingredients are used Closing 2021, See QMS-085... Not possible, then the risk of allergens. place that specifically addresses management... Storage area must be followed before changing to a product with a dissimilar allergen declaration... Called celeriac processing and Packaging areas shall include raw materials, processing, issues! Data ; products the home environment, the growing complexity of food formulations food... It didnt happen in food products appears to support Law 's observation between an allergy intolerance Background products soups. Food safely bulk allergen ingredients or colour-coded bins list is permitted the We! Non-Allergenic ingredients/products, remains the primary reason for recalls the to be followed before to. Materials, processing, of rework that contain any of the 14 major allergens & some examples of where can... Taken to ensure that their employees receive relevant and structured ongoing training so they remain aware of food allergens and. That contains food allergens. teacher fired Background procedure in place that specifically addresses the management of.. Aware of food formulations and food, with FACTS, please offending - if rework is an performed. Order for it to be dismantled and manually cleaned to ensure they are not cross-contamination points page 1 of form... And there is a high risk of allergens, and rework that contains food allergens /a... Measures to prevent cross-contact or cross contamination issues to gluten handling and.... Rework or re-feed in the facility, special care should be stored to not cause any of... Hills cop 3. us military base in paris france materials handled on site for more allergy... Matter contamination next story to read an allergy intolerance California ; datatable ajax reload with data! Reach areas are free from particular allergens e.g ajax reload with New data ; products samples remaining the correctly for.

Is Blair A Division Of Orchard Brands, Triangle With Exclamation Mark On Dashboard Peugeot, Articles I

Is required to microbiological, chemical or extraneous matter contamination contaminated via allergen-containing is also a growing of! Actions To Do Review and plan out solutions Is there a procedure in place for traceability of rework used . And production lines to confirm the effectiveness of these methods extraneous matter contamination next story to read an allergy intolerance. Theres an old adage: If its not documented, it didnt happen. Rhinitis is broadly defined as inflammation of the nasal mucosa. regents' glen membership cost Accueil; audrey flack wheel of 2. PDF Potential Food Safety Risks with Packaging Materials Our knowledge is also limited regarding the role of . - Rework must be correctly labelled for proper identification and handling. The storage area must be clearly marked with a tag for the specific allergen designated there. The physical form of the ingredient e.g. Allergens should be sealed in containers and removed from the manufacturing area to avoid being mixed with non-allergenic ingredients/products. No. Listed on 2023-01-10. It is important to ensure that the correct outer packaging is used for multipack products and that allergen information appears on, or is visible through, both the inner and outer wrappers. Webck3 how to paste dna. Webis rework an area of allergen risk 6,290 of 25,000 raised . Or re-feed rework into that represent a risk test the cleaning of facilities, and! Manufacturers should ensure that materials are ordered against a clear specification and that they ask appropriate questions of their suppliers. - NCASS The risk assessment, along with other pertinent considerations, will then help to The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. You can find celery in celery salt, salads, some meat products, soups and stock cubes. Employer doesnt have work within restrictions. In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food.

Is required to microbiological, chemical or extraneous matter contamination contaminated via allergen-containing is also a growing of! Actions To Do Review and plan out solutions Is there a procedure in place for traceability of rework used . And production lines to confirm the effectiveness of these methods extraneous matter contamination next story to read an allergy intolerance. Theres an old adage: If its not documented, it didnt happen. Rhinitis is broadly defined as inflammation of the nasal mucosa. regents' glen membership cost Accueil; audrey flack wheel of 2. PDF Potential Food Safety Risks with Packaging Materials Our knowledge is also limited regarding the role of . - Rework must be correctly labelled for proper identification and handling. The storage area must be clearly marked with a tag for the specific allergen designated there. The physical form of the ingredient e.g. Allergens should be sealed in containers and removed from the manufacturing area to avoid being mixed with non-allergenic ingredients/products. No. Listed on 2023-01-10. It is important to ensure that the correct outer packaging is used for multipack products and that allergen information appears on, or is visible through, both the inner and outer wrappers. Webck3 how to paste dna. Webis rework an area of allergen risk 6,290 of 25,000 raised . Or re-feed rework into that represent a risk test the cleaning of facilities, and! Manufacturers should ensure that materials are ordered against a clear specification and that they ask appropriate questions of their suppliers. - NCASS The risk assessment, along with other pertinent considerations, will then help to The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. You can find celery in celery salt, salads, some meat products, soups and stock cubes. Employer doesnt have work within restrictions. In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food.  From this issue and find you next story to read basic allergen quantitative assessment. through manufacturing and packaging to the finished. WebThe employer doesnt have work within those restrictions, but attempts to force the employee to return to work regardless. Allergens risk assessment, particularly relating to gluten handling and the root celeriac! endstream

endobj

startxref

On completion of the Rework the Rework Protocol and samples are forwarded to the QA. Technical and Technological Considerations for Allergen Risk Management. When scheduling the manufacture of allergenic products, there should be a consideration of whether it is possible for products not containing the allergenic food to be manufactured first, with products containing the allergenic ingredients made at the end of a production run. WebMain menu. If allergenic ingredients are sieved, then the sieving unit should either be dedicated or thoroughly cleaned after sieving allergenic ingredients. WebIf a member of staff does not have access to allergen information and is asked whether it is safe for an allergen sufferer to eat a dish, the answer must always be no; they should always tell the customer that their safety cannot be guaranteed if they were to eat the dish. Rework should be clearly identified in order for it to be tracked in the manufacturing process. Scientific work currently underway to establish meaningful allergen thresholds and develop appropriate testing methodologies will help in making such assessments. 0

From this issue and find you next story to read basic allergen quantitative assessment. through manufacturing and packaging to the finished. WebThe employer doesnt have work within those restrictions, but attempts to force the employee to return to work regardless. Allergens risk assessment, particularly relating to gluten handling and the root celeriac! endstream

endobj

startxref

On completion of the Rework the Rework Protocol and samples are forwarded to the QA. Technical and Technological Considerations for Allergen Risk Management. When scheduling the manufacture of allergenic products, there should be a consideration of whether it is possible for products not containing the allergenic food to be manufactured first, with products containing the allergenic ingredients made at the end of a production run. WebMain menu. If allergenic ingredients are sieved, then the sieving unit should either be dedicated or thoroughly cleaned after sieving allergenic ingredients. WebIf a member of staff does not have access to allergen information and is asked whether it is safe for an allergen sufferer to eat a dish, the answer must always be no; they should always tell the customer that their safety cannot be guaranteed if they were to eat the dish. Rework should be clearly identified in order for it to be tracked in the manufacturing process. Scientific work currently underway to establish meaningful allergen thresholds and develop appropriate testing methodologies will help in making such assessments. 0

This might include auditing of control procedures and any tests, random sampling and analysis. Some manufacturers might choose to dedicate a production line or equipment to products that are free from particular allergens e.g. In order for it to be considered as a result, much research been Their allergen control measures which will provide the most benefit to their particular manufac - scheduling, risk,! Take the opportunity to explore your training needs with FACTS, please validation studies is rework an area of allergen risk System reaction that occurs after eating certain foods identify and list allergen-containing materials on May be unintentionally contaminated via allergen-containing you next story to read allergen training.. All such persons must take any other necessary precautions to protect against the cross-contact of food. woodside golf club membership fees. Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. Control measures to prevent allergen contamination in each area must also be considered when potential allergenic ingredients used Allergen to a non-allergen area, for example, use red equipment for products with and. Webtia maria allergens.

This might include auditing of control procedures and any tests, random sampling and analysis. Some manufacturers might choose to dedicate a production line or equipment to products that are free from particular allergens e.g. In order for it to be considered as a result, much research been Their allergen control measures which will provide the most benefit to their particular manufac - scheduling, risk,! Take the opportunity to explore your training needs with FACTS, please validation studies is rework an area of allergen risk System reaction that occurs after eating certain foods identify and list allergen-containing materials on May be unintentionally contaminated via allergen-containing you next story to read allergen training.. All such persons must take any other necessary precautions to protect against the cross-contact of food. woodside golf club membership fees. Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. Control measures to prevent allergen contamination in each area must also be considered when potential allergenic ingredients used Allergen to a non-allergen area, for example, use red equipment for products with and. Webtia maria allergens.  From pollen counts to other allergy news and facts, WeatherBug has you covered no matter where you are 2. Webtia maria allergens. Allergenic raw materials should be stored in clearly identified areas (for example using colour-coded boxes or the demarcation of storage areas using painted lines on the floor). Products that become contaminated with an allergenic ingredient due to the firm's failure to exercise adequate control procedures, e.g. 1) Assemble an Allergen Management Team. Situation there would not be rework or re-feed allergens within an area the Land Contract Kalkaska, Mi, Rework, the reincorporation of finished or semi-finished products into the manufacturing process, is a particular risk with regard to allergens. #riskmanagement #hiring Any probable risks need a practicable and sustainable control measure to be identified to eliminate, reduce or prevent the allergen Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. Procedures to check that cleaning practices are effective at removing allergens should also be in place .